How We Make with Precision Equipment What Our Customers Envision Precise Industries Inc. is a leading precision sheet metal fabricator and machine shop of a variety of products.

Large and small runs for your precision Sheet Metal or Machining needs . This is why they send their designs for custom items to Precise Industries. Our team and equipment following quality control processes delivers parts to our customers that meet their every requirement.

Precision objects typically pass through several specialized machines to be finished. These may include a milling machine, lathe, stamp press, shear or press-brake. The Precise Industries shop includes quality processes, workflow programs and inspection equipment to deliver precision crafted objects with our machining and sheet metal equipment

Workflow and Process Programs

- Solidworks - 3D CAD software

- Fabriwin - CAD/CAM software system that improves sheet metal fabrication productivity and quality

- Mastercam - machinists software for computer numerical controlled (CNC) machine tools

- FeatureCAM - CAM system that combines automation with control for 2D and 3D milling, 5-axis simultaneous machining, high-speed milling, turning, turn/mill and live tooling

- JobBOSS - Shop management and integrated control software

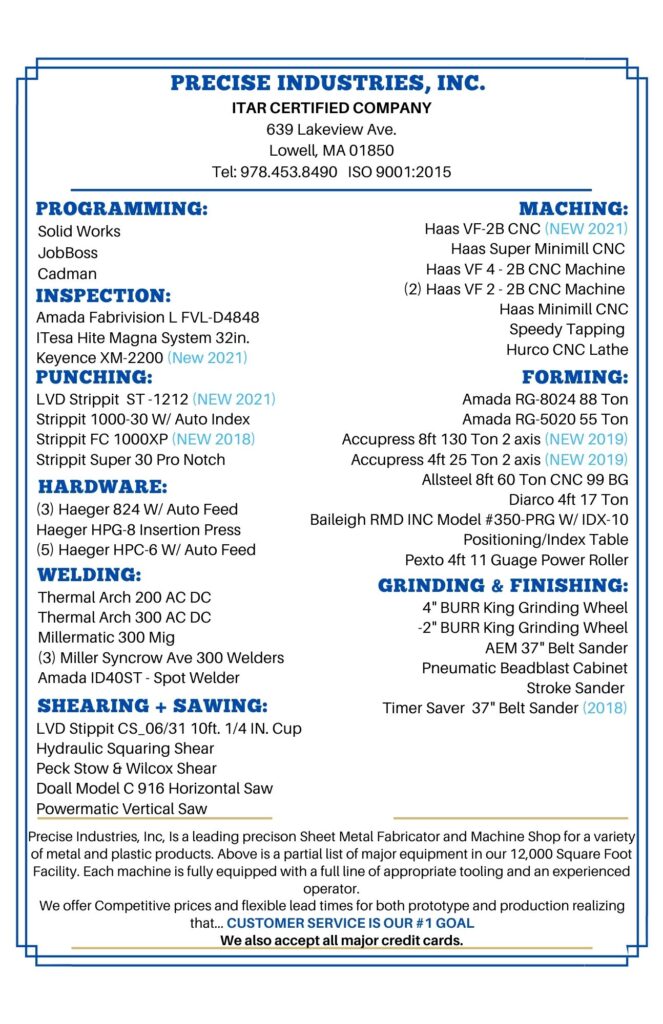

FACILITIES LIST

Here are just some of our many machines used to Create your vision