Punching

Our CNC punching services deliver accurate, repeatable results for parts with complex shapes, patterns, and perforations. With three punch press machines we are able to keep up with any work demands

Capabilities:

- High-speed CNC thin turret punching

- LVD CADMAN Programming

- Up to 40 stations per machine

- Large inventory of tooling

- Blank Sizes up to 50’’ x 120’’

- Precision hole patterns and custom shapes

- Forming, embossing, and countersinking features, part marking

- Wide Range of Materials and Thickness

- Aluminums

- Stainless Steel

- Brass

- Copper

- Mild Steel

- Plastics

- Short-run or high-volume production

We ensure clean edges, tight tolerances, and consistent quality across every part.

Machining

We provide CNC machining services for both simple and highly complex components. Precise Industries offers a full machine with 6 CNC mills and 1 CNC lathe allows us to manage demanding workloads efficiently and consistently.

Capabilities:

- CNC horizontal milling and turning

- CAD Programming Software

- Multiple 10000 RPM spindles

- 30 Tool Holding Stations

- Probing

- Rotary and Indexers Capabilities

- High Speed Machining

- Up to (x) 50’’ x (y) 20’’ x (z) 25’’

- Tight tolerance machining

- Prototype and production runs

- Wide Range of Workable Materials (Not limited to)

- Aluminums

- Mild Steel

- Tool Steel

- Stainless Steel

- Brass Alloys

- Copper Alloys

- Wide range of Plastics

Our machinists deliver accuracy and repeatability to meet exact customer specifications.

Welding

Our certified welders specialize in producing strong, clean, and reliable welds for structural and precision applications.

Capabilities:

- MIG, TIG, and spot welding

- Two AWS D17.1 Certified Welders

- 5 Tig Welding Stations

- Steel, stainless, and aluminum

- Fabrication of assemblies and subassemblies

- Weld inspections and quality verification

- Over 100 years of experience between our welding team collectively

Whether you need light-gauge welding or heavy-duty fabrication, we ensure quality with every weld.

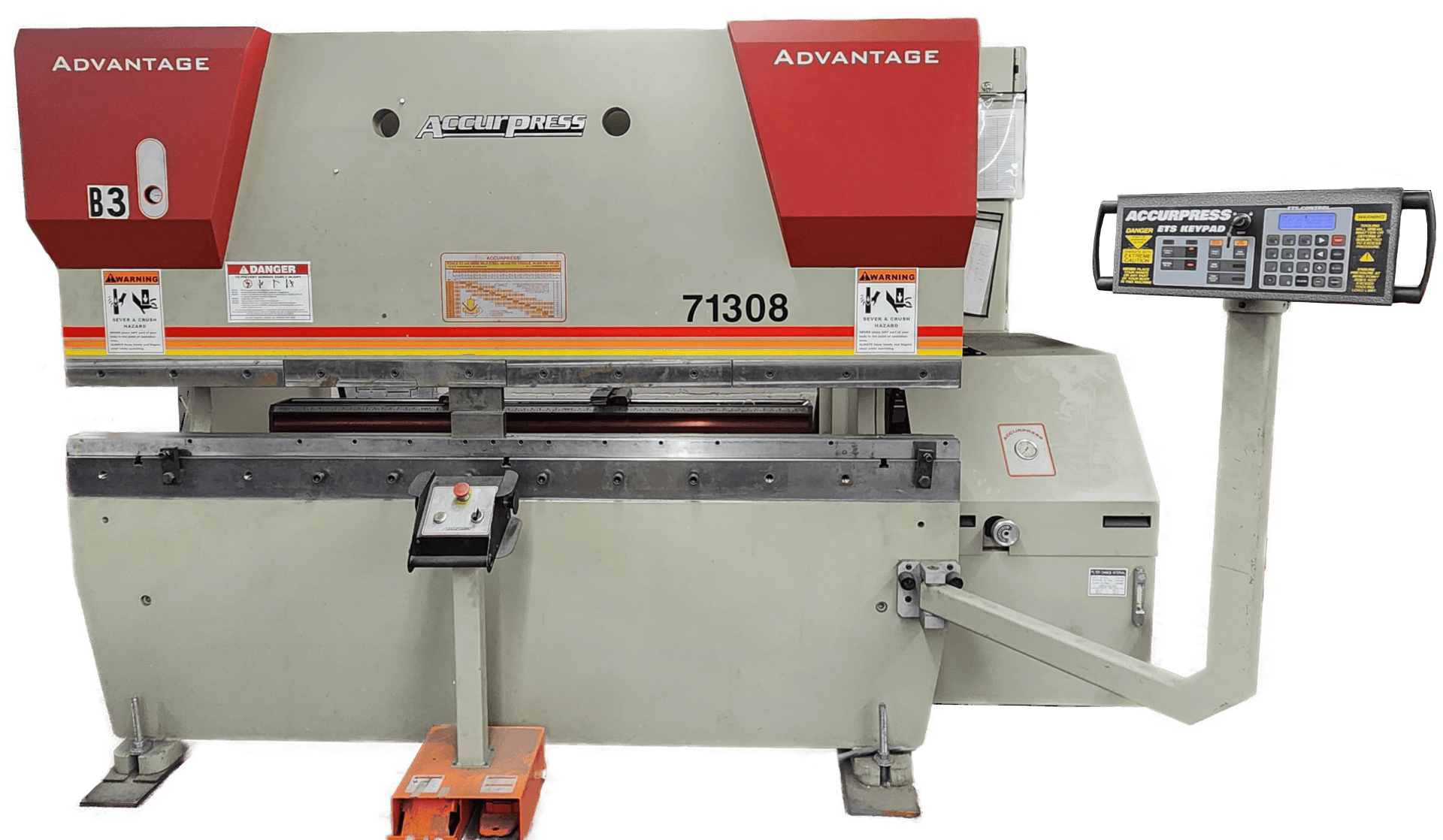

Forming

Our press brake forming department produces precise bends and complex shapes with accuracy and consistency.

Capabilities:

- CNC press brake forming

- 48” Baileigh Roller

- Six press brake station

- Up to 8’ bends w/ 130 Ton

- Precision Tooling

- Multi-bend and radius forming

- Repeatability for large production runs

- Wide Range of Material thicknesses

- Press Brake Operators with 100 years’ experience collectively

We ensure exact angles, clean edges, and high-quality finishes.

Hardware

We offer complete hardware installation services for mechanical fasteners and components.

Capabilities:

- PEM fasteners (nuts, studs, standoffs, etc.)

- Riveting and clinching

- Mechanical assembly and subassembly work

- Multiple Auto Feeds for both Studs and Nuts

- Inventory system to ensure stock on hardware

- 6 Haeger Works stations

We streamline production by making your parts assembly-ready when they leave our facility.

Quality Department

Quality Management System (QMS) Capabilities:

- ISO 9001 and ITAR compliance and certification

- Documented procedures, work instructions, and process controls

- corrective/preventive actions (CAPA)

- Internal auditing program

- Supplier quality management and qualification

- Control of non-conforming product (NCR process)

- UniPoint Quality Software

- First Article Inspections (When requested)

- XM Keyence CMM Inspection

- Amanda Fabri Vision for 1st pc inspections

- Calibration Schedule

- Operator training procedures

- JobBoss Shop Flo Software